Bag Filter Efficiency Calculation

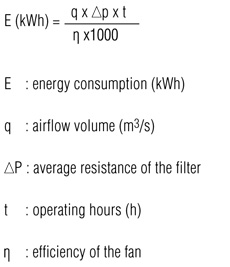

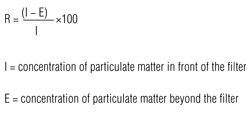

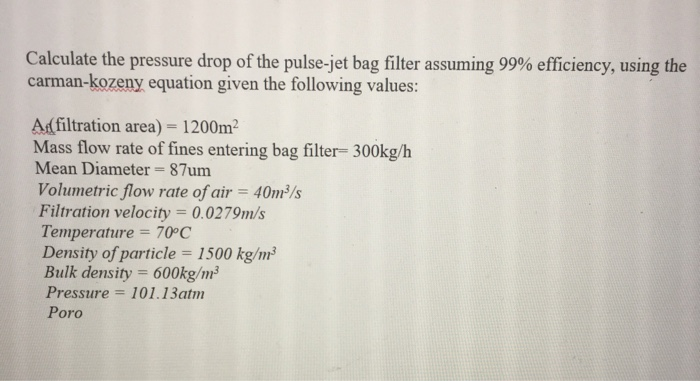

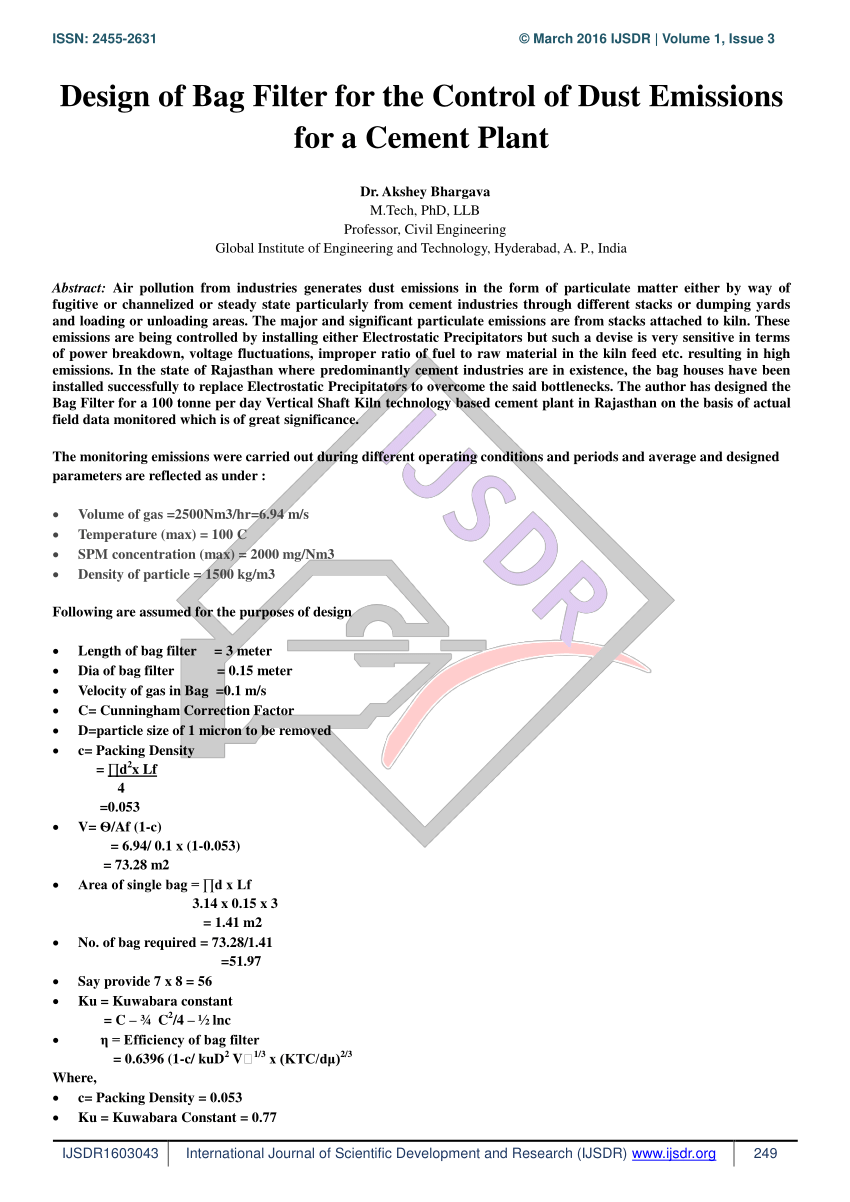

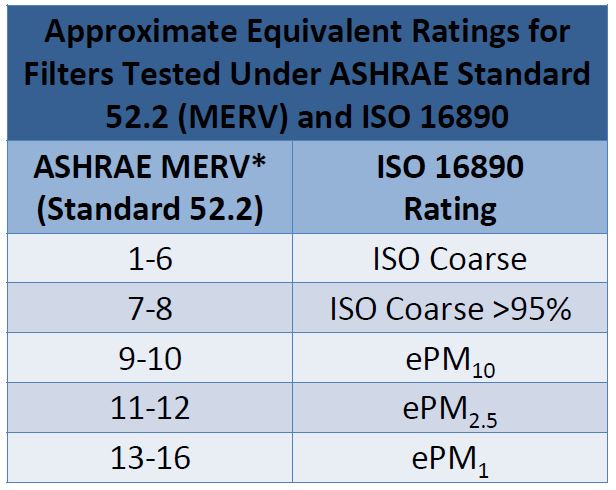

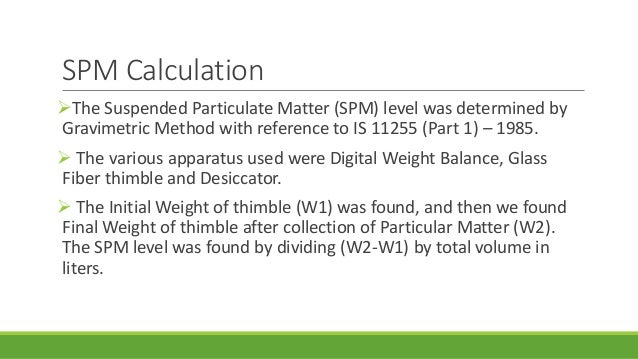

Bag filter efficiency calculation. Tion efficiency of greater than 99. Typical values of system pressure drop range from about 5 to 20 inches of water. 7-3 P media k 1 v f Where.

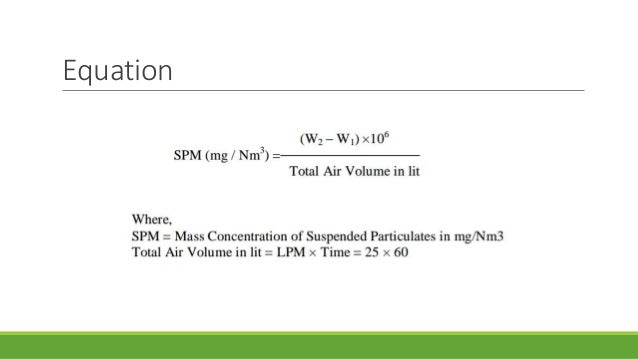

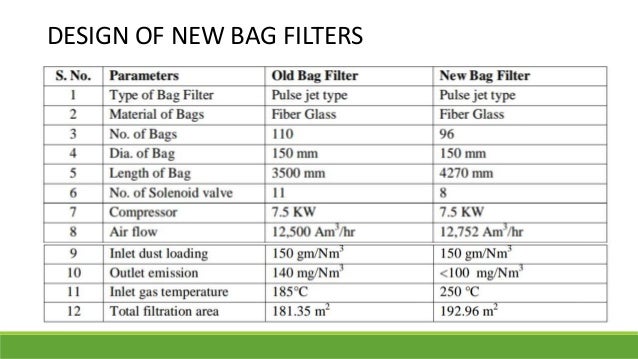

Step 1Select the type of bag micron rating and flow rate determine the pressure drop for water 1 cps 68F for a size 2 bag. Then Click on Calculate To Find the Interstitial Velocity. Air quantity Q1 069 m3s.

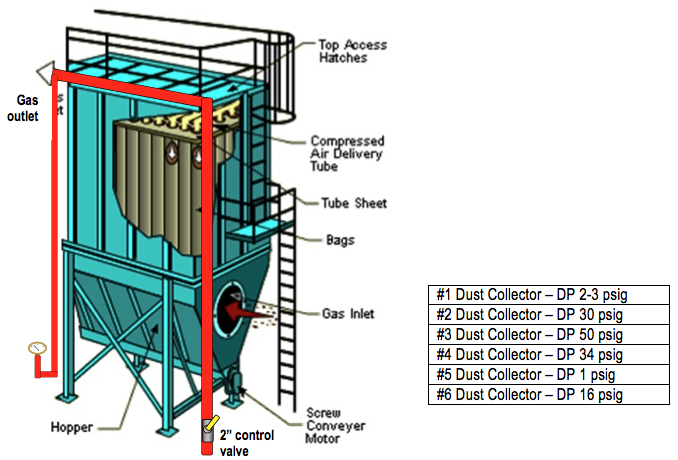

Capture Velocity Vc 08 ms powder. B x is the Beta Ratio for a filter for trapping particles of x microns. Pressure drop across the bags and associated hardware and ducting.

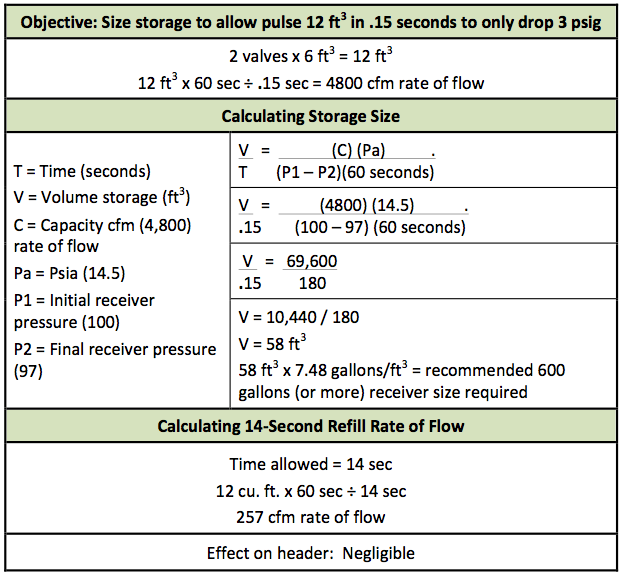

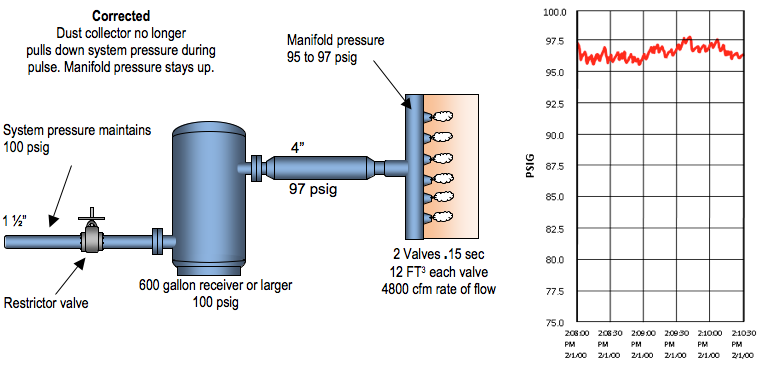

SYSTEM PRESSURE DROP PS PH PB When sizing new applications the PS should be 20 PSI or less. The lower this value is the more contaminant a filter bag will hold. Enter ACFM of Air Side L in Side w in - Bag Dia2² π of Bags.

T The Nuclear Air Cleaning Handbook recommended 998 efficiency for the first stage and 999 to 9995 for each of the remaining stages. To determine the pressure drop caused by the filter bag follow these steps. Several factors determine fabric filter collection efficiency.

Hood Size m x m H1 093 x 093. Ric filter system is the sum of the costs of the baghouse bags auxiliary equip-ment instruments and controls. Calculate the number of bags required in a baghouse for a given process flow rate 4.

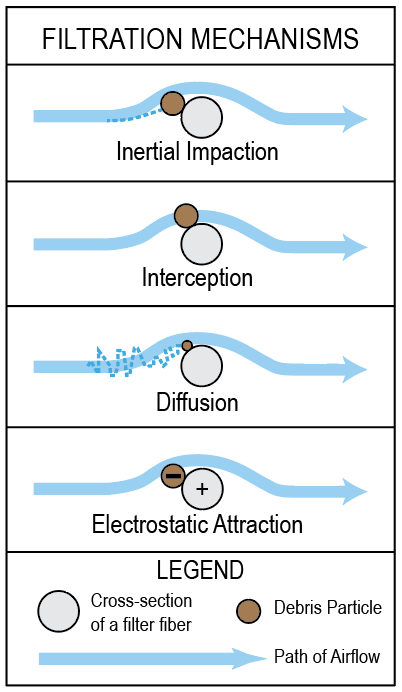

In general collection efficiency increases with. Head loss in a clean filter Carmen Kozeny equation.

P media pressure drop across filter media in.

Step 2Correct for bag size from the Bag Size Correction table at. The last three items generally are taken as percentages of the estimated total cost of the first three items. P dust cake pressure drop across dust cake in. Air quantity Q1 069 m3s. T The Nuclear Air Cleaning Handbook recommended 998 efficiency for the first stage and 999 to 9995 for each of the remaining stages. Head loss in a clean filter Carmen Kozeny equation. 3 ms lumps. Typical values of system pressure drop range from about 5 to 20 inches of water. WCftmin v f velocity through filter ftmin 7-4 P dust cake k 2 c i v f 2 t Where.

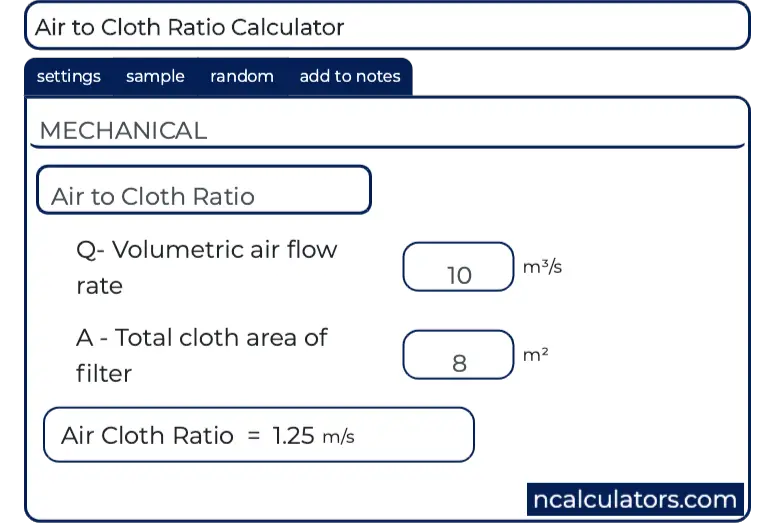

Calculate the number of bags required in a baghouse for a given process flow rate 4. These include gas filtration velocity particle characteristics fabric characteristics and cleaning mechanism. Then Click on Calculate To Find the Interstitial Velocity. Pressure drop across the bags and associated hardware and ducting. V the grain volume. 2 v A V g k L h 3 12 A d V 6 A s Q v Where k dimensionless coefficient 5 for sand 6 for anthracite. Take the CFM of the system and divide it by the total filter cloth area to get your air to cloth ratio.

Post a Comment for "Bag Filter Efficiency Calculation"