Thermal Spray Coating Applications

Thermal spray coating applications. Application of thermally sprayed coatings for the preservation and maintenance of steel structures and components. Every thermal spray coating process begins with choosing the right material for applying on the substrate. Thermal spray coatings are applied to a substrate to give a specifi c surface quali-ty which it originally does not have.

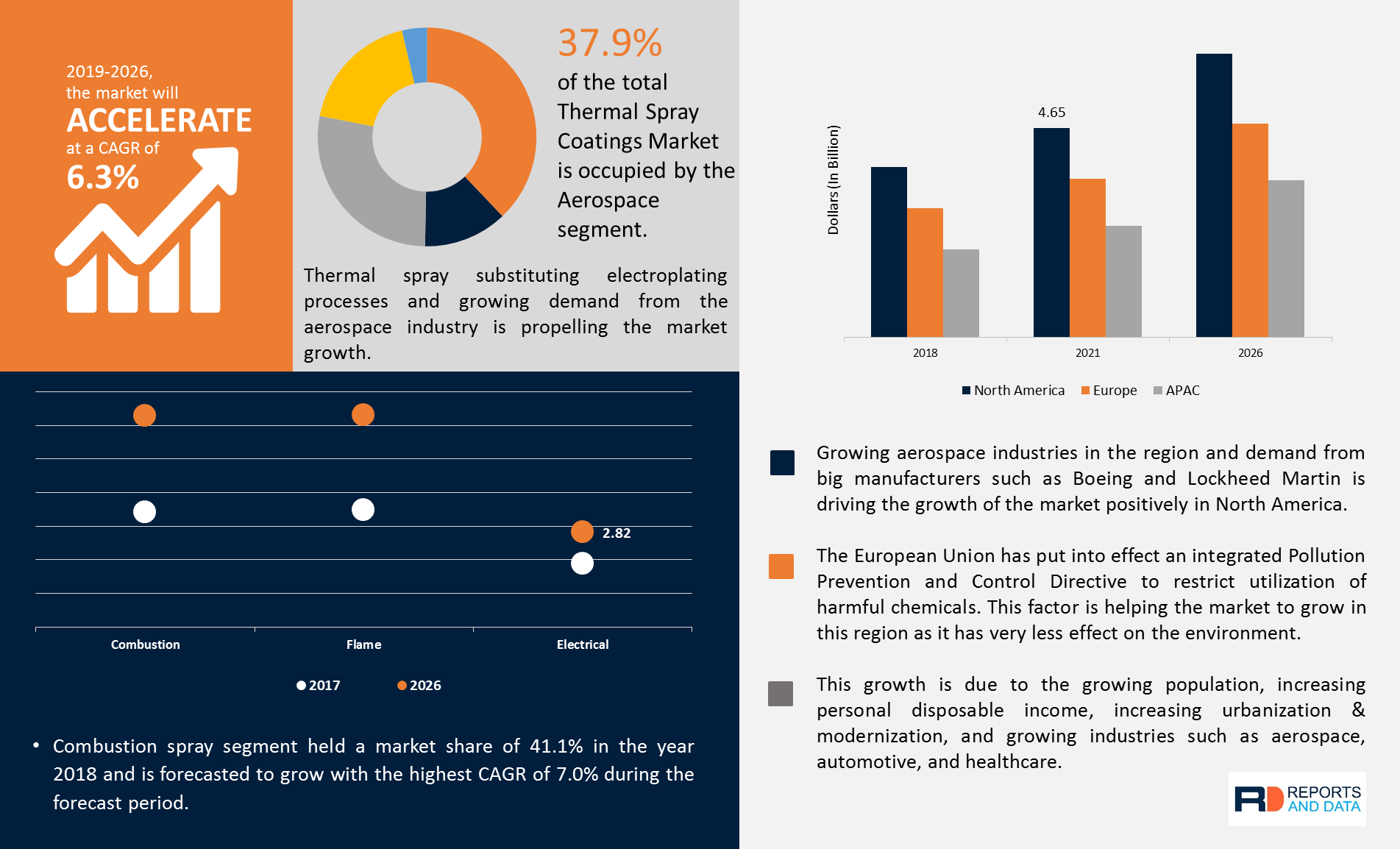

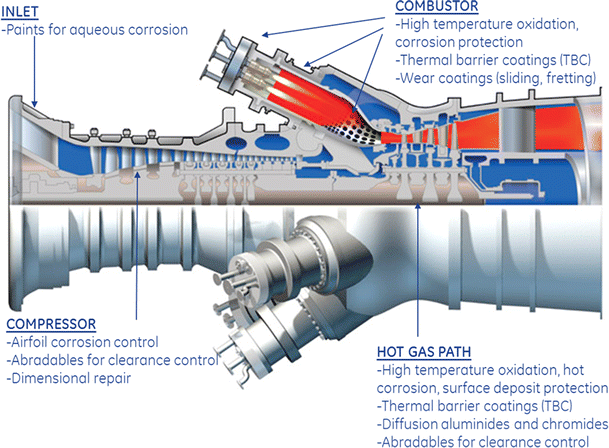

Thermal sprayed abradable seal coatings are used to control gas path clearance in gas turbine engines. Contact us today to discuss the best thermal spray option for the job in your specific industry. Most applications of thermal spray coating and hard chrome plating include machines that involve many moving or rotating parts.

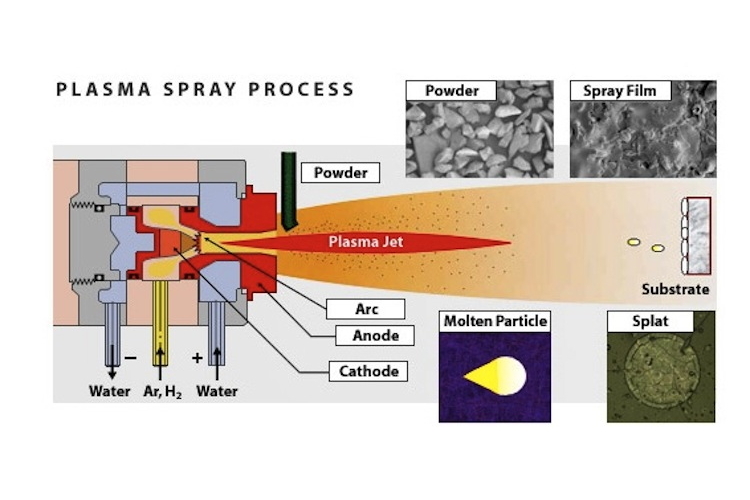

Is melted can be used as a thermal spray coating mate-rial. Engineering coatings can provide such properties as enhanced wear resistance thermal barriers electrical thermal conductivity hard-chrome replacement and insulation across a wide range of applications. Different types of coating materials and processes have different properties.

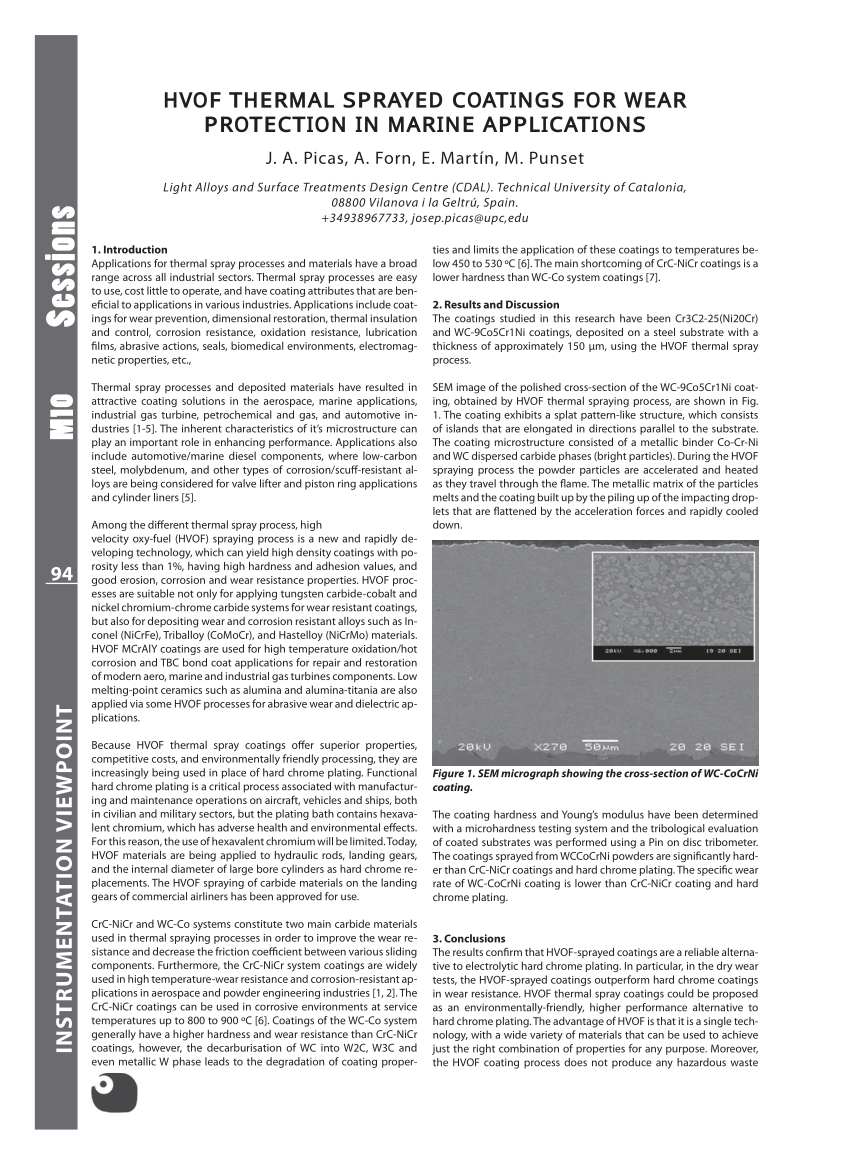

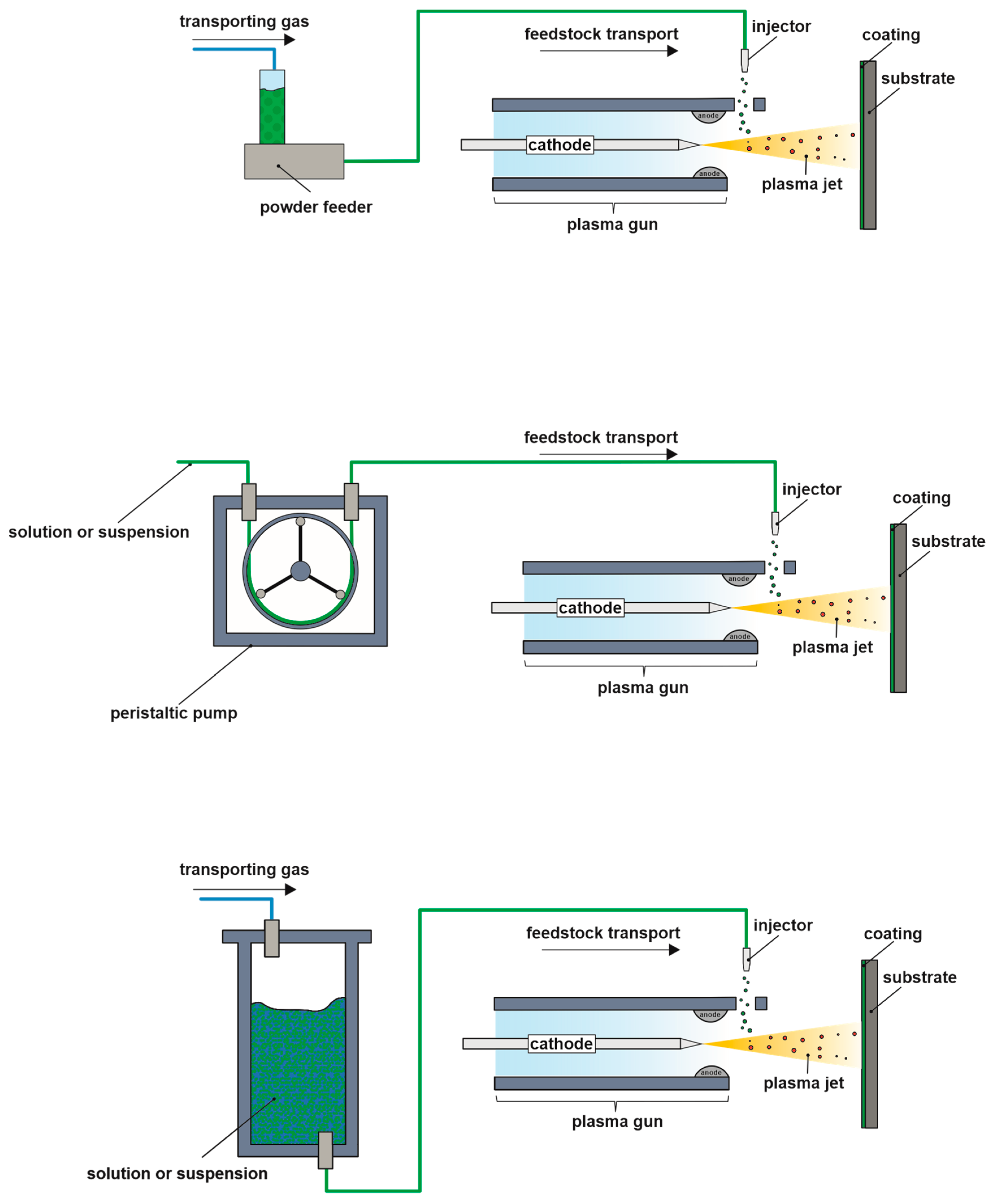

Thus the bulk strength of a part is given by the substrate and the coating adds superior surface qualities such as corrosion wear or heat resistance. Among different thermal spray coating techniques high velocity oxygen fuel HVOF and plasma is the most commonly thermal spraying coating process to. We provide coatings and restoration services for a wide range of industrial applications.

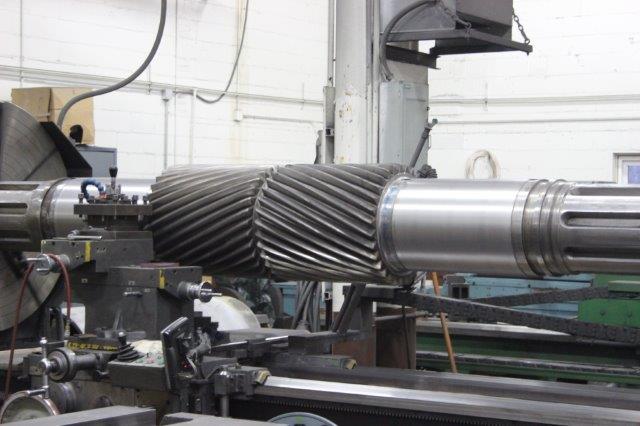

Click here to view our various application services. Solar Thermal Mirror Coatings Can Provide Corrosion Protection One of the greatest discoveries of modern science is the fact that from sunshine a concentrated production of energy is. Thermal spray coatings are used to restore the dimensions of components that have been worn or corroded such as printing rolls and undersized bearings.

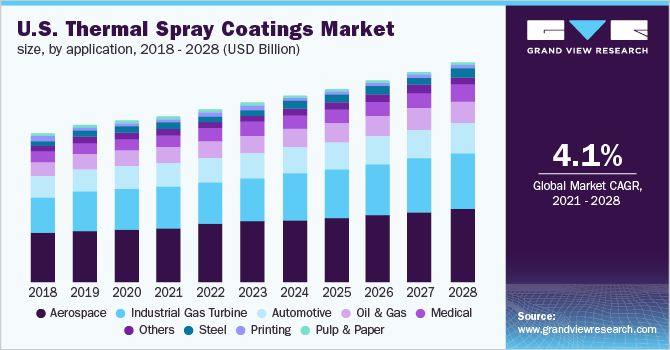

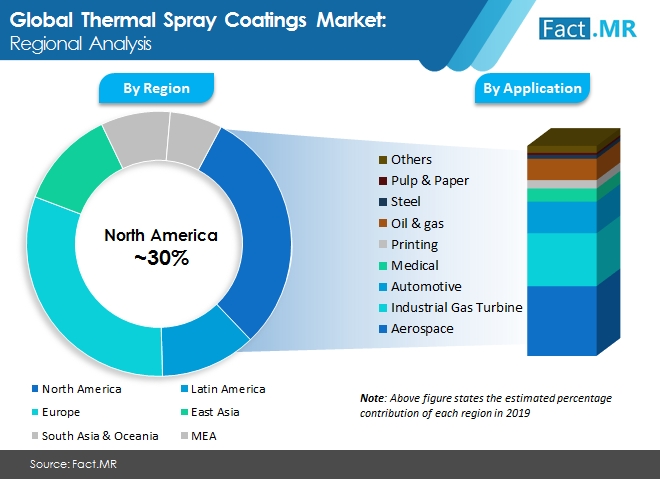

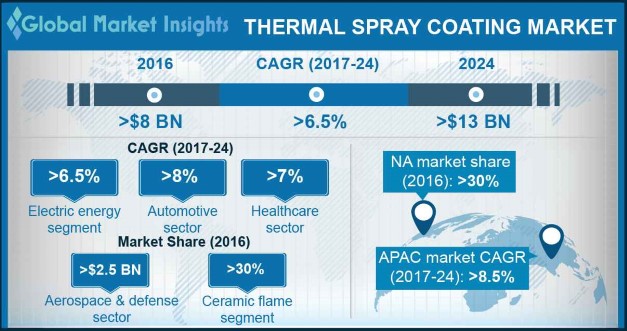

The major benefits of clearance control coatings are increased engine efficiency and reduced fuel consumption. Thermal spray coating applications according to industry served. Thermal Spray applications and benefits A range of applications across numerous industries include crankshaft reconditioning and corrosion protection.

In addition to original equipment applications thermal spray coatings are used to repair parts worn and damaged in service and restore dimensions to machined parts. Depending on the thermal spray process the coat-ing material can be in wire or powder form.

Thermal spray coating applications according to industry served.

Applications The TSA Corrosion Protection System offers a wide range of benefits. In Table 2 some of the most frequently used classes of materials are listed along with a typical example char-acteristics and sample applications. We provide coatings and restoration services for a wide range of industrial applications. Applications The TSA Corrosion Protection System offers a wide range of benefits. Contact us today to discuss the best thermal spray option for the job in your specific industry. Thermal spray coatings are used to restore the dimensions of components that have been worn or corroded such as printing rolls and undersized bearings. Application of thermally sprayed coatings for the preservation and maintenance of steel structures and components. Key applications for thermal spray coatings in the aerospace and IGT segments can be seen below. Thermal spray coatings are applied to a substrate to give a specifi c surface quali-ty which it originally does not have.

Solar Thermal Mirror Coatings Can Provide Corrosion Protection One of the greatest discoveries of modern science is the fact that from sunshine a concentrated production of energy is. Is melted can be used as a thermal spray coating mate-rial. Contact us today to discuss the best thermal spray option for the job in your specific industry. The spray technique is faster than many other coating application techniques. Among different thermal spray coating techniques high velocity oxygen fuel HVOF and plasma is the most commonly thermal spraying coating process to. The heat source melts the coating material into drops that can be sprayed onto the surface. Users will realize significant savings in installed and long-term maintenance costs because the need for sacrificial anodes is reduced and coating repair is unnecessary.

Post a Comment for "Thermal Spray Coating Applications"